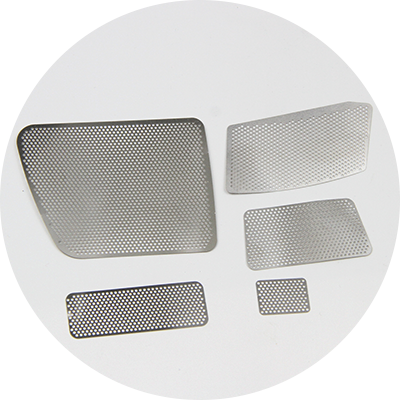

Precision Photo Chemical Etching

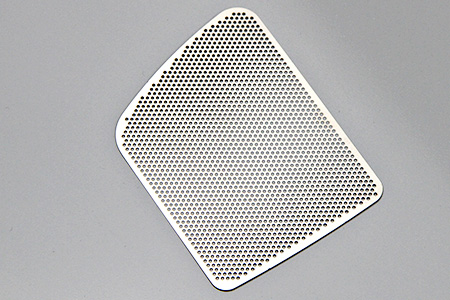

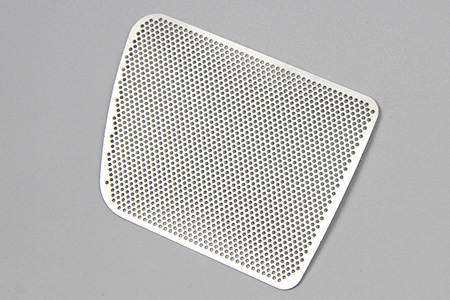

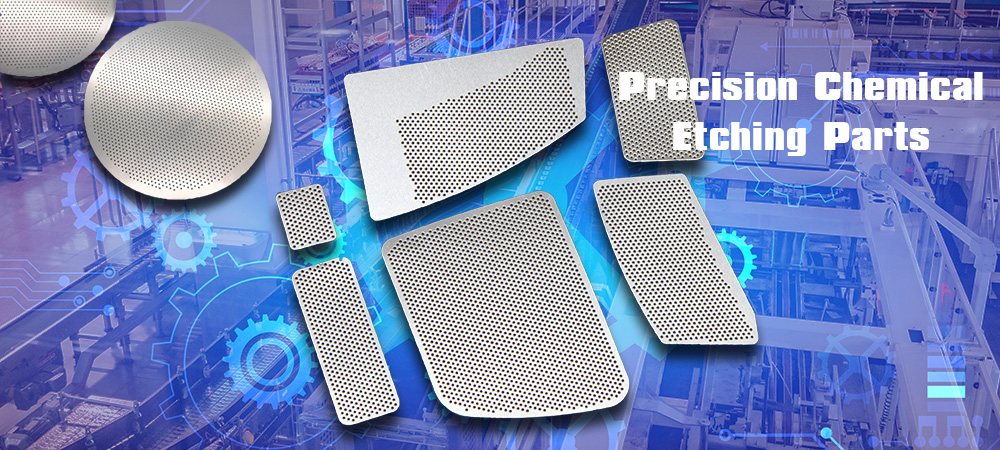

Photo etched screens can have extremely precise, intricate features, thanks to our state-of-the-art chemical etching process. Our etching process allows us to create metal screens with very fine webs and holes. These have a high degree of dimensional stability, so they stand up to stress during etching, handling and use in demanding applications.

An etched screen may also be used in food-grade and clean room applications. In fact, photo etched screens are suited for the most sensitive technological requirements because they are extremely flexible and versatile.

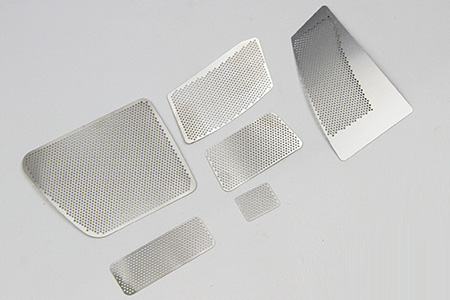

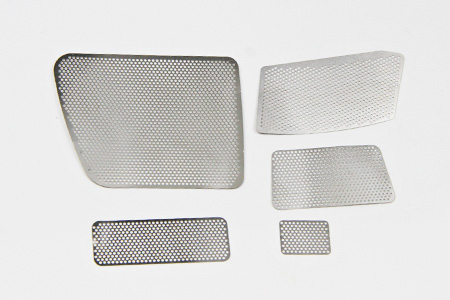

Product Display

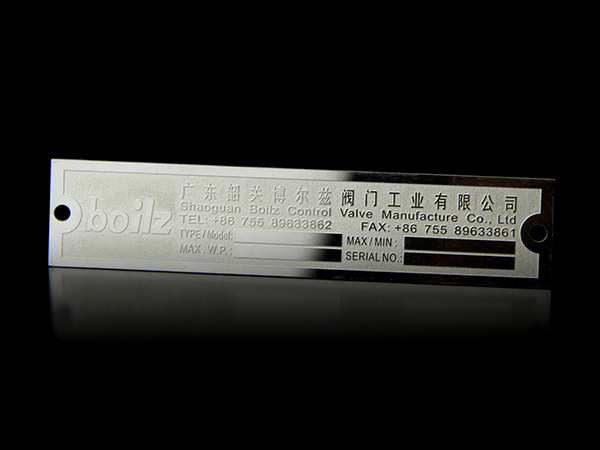

Product Details

Application Area

- Electronic equipment: RFI filters, particle filters, PCB shielding, speaker grilles, and water filtration equipment.

- Medical equipment: Filters, sensors, monitoring devices, surgical needle threaders, and medical implants.

- Military and aerospace: Fuel and hydraulic system filters, cabin air quality systems, and noise reduction components.

- An etched screen may also be used in food-grade and clean room applications. In fact, photo etched screens are suited for the most sensitive technological requirements because they are extremely flexible and versatile.

| SPECIFICATIONS | |

| Product | Photo Chemical Etching/Photochemical Machining |

| Material | Aluminum, Brass, Bronze, Copper, Precious Metals, Stainless Stee |

| Thickness | 0.15-2 mm |

| Finish | Brushed/ Polished/ Plated/ Anodized /Matte /Glossy steel, etc. |

| Macnining | Photo chemical milling/ Etching |

| Coating | Plating/ Anodization/ Printing/ Sandblasted/ Powder coated |

| CNC Machining or Not: | Not CNC Machining |

| Photochemical etching: | Microetching plate |

| Application | For precision metal parts |

| Production Time | 3-7 Working days for samples,7-15 working days for mass production |

| Delivery | Delivered by airfreight with 1-5 working days, By sea for huge heavy goods 30days |

Choose The Material

Various materials to meet your demands, for different products, choose different raw materials according to process.

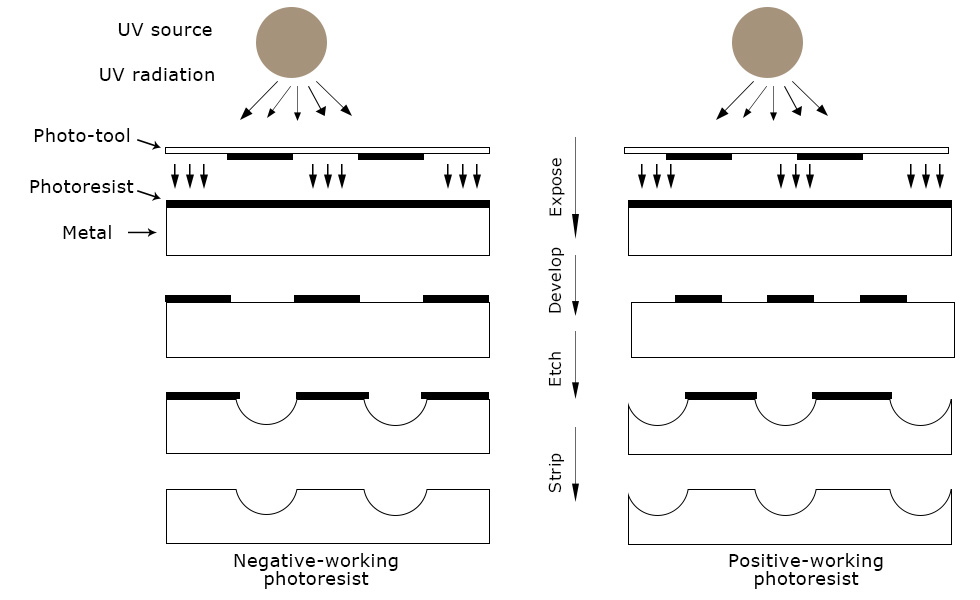

technological process

- Once the metal type is selected, it is cut into thin sheets, cleaned, and prepared for etching. A photosensitive material, or photoresist, is added to the sheet using a coating system. The photoresist is acid-resistant and light-sensitive. A reusable plotter film includes all the part characteristics, so the same part can be produced as many times as needed. High quantities can be produced at low production costs.

- The metal sheet is then placed between two pieces of photographic film (tooling) detailed above and exposed on both sides to ultraviolet (UV) light. The exposed resist becomes hardened, while shaded areas of the resist remain soft. The softer resist is washed away during development, leaving behind exposed material for the heated etchant to dissolve. The hardened resist will protect the desired material from the etchant to create the desired parts.

- After chemicals are applied, the photoresist is removed, and the metal parts are inspected to ensure they meet the customer’s specifications.

Customize your photo chemical etching metal parts NOW!! Contact us info@greatnameplates.com Various sizes, shapes, and processes, we will produce it for you immediately